When data consistency makes the difference

Monheim, 2024-11-13

End-to-end data consistency and data quality in a project is becoming increasingly important for rapid project success. Solutions provider EPLAN offers comprehensive support in this area – including data packages for users made up of standardisation templates, industrial templates and application examples. Standards such as IEC 81346 are immediately applied and the goal is clearly defined: companies should ideally be able to build on integrated data from the start to the finish, meaning from preplanning through to service, and quickly get started with this.

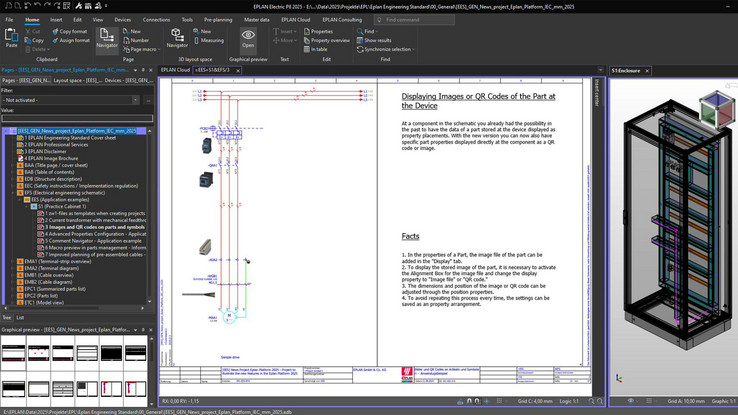

A new feature is the News Project for the Eplan Platform 2025: the data package includes detailed information about the update and enables users to test the new functions directly in the software.

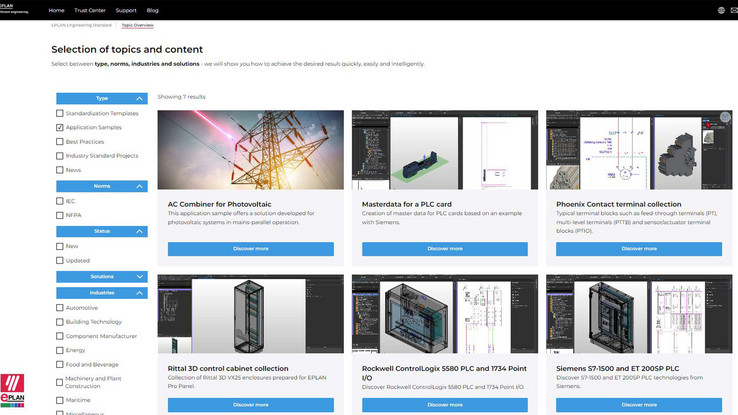

Admittedly, a transformer station being presented as an exhibit at the SPS is in and of itself is not terribly new. However, it comes with the pertinent industrial project – a completely pre-designed EPLAN Project that makes it easier for users to get started with the engineering of medium-voltage and low-voltage systems. On the topic of HVAC, there is another industrial project already based on the new AMEV BACtwin 2024 and that simplifies preplanning for building automation. These are just two examples of the more than thirty data packages that EPLAN provides for its users. Application examples for 3D control cabinet engineering using EPLAN Pro Panel and the Rittal VX25, as well as AX and KX enclosures, contain preconfigured wire ducts and mounting rails. There is additionally an example of best practices on the topic of data exchange between EPLAN and the Siemens TIA Selection Tool and the Siemens TIA Portal addressing the transfer of data from electrical engineering to automation.

News on the EPLAN Platform

In the framework of the EPLAN Engineering Standard (EES), it is always about well thought-out data to improve customer processes and simply make it quicker and easier for first-time users to get started – with a high degree of integration and standardisation for fast and high-quality results. A new feature is the News Project for the EPLAN Platform 2025: the data package includes detailed information about the update and enables users to test the new functions directly in the software.

A focus on functional engineering

Electrical engineers are faced with the challenge of creating schematics that are easy for anyone to read. However, a control cabinet manufacturer needs different information than a service or maintenance technician. How do companies ensure that their schematics contain all the information different end users need? This is where functional engineering comes into play: EPLAN is presenting corresponding solutions at the SPS because they are in high demand and create leverage to accelerate processes and thereby increase efficiency.

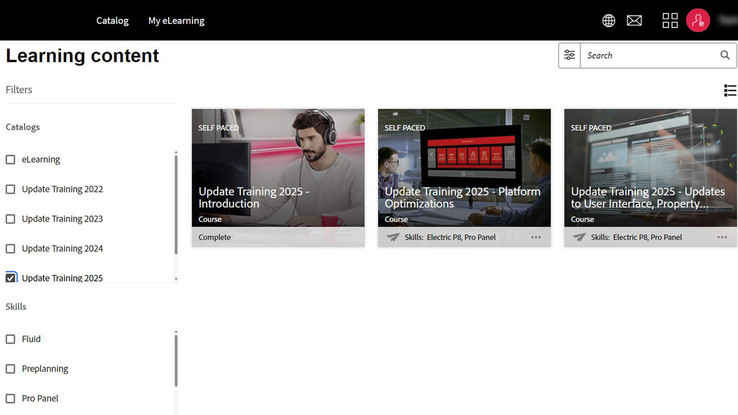

With the eLearning “Eplan Platform 2025 Update Training,” users can easily discover new functions and get tips on project planning, which can help them achieve better results even faster.

The data packages Eplan offers users contain standardisation templates, industrial templates and application examples – all based on the Eplan Engineering Standard (EES).

All components are clear

The method of functional engineering saves time and ensure correct, error-free data. With function-oriented engineering, all components that belong together functionally are part of a single set of schematics. This makes changes and the addition or removal of components much easier. Functional planning consolidates almost all components of an electro-mechanical construction that are connected by technical aspects. For instance, a motor system with wires, terminals, relays, contactors, safety components, PLC inputs and outputs, etc. in a control cabinet is responsible for controlling the same function. The complete function is shown on a few pages of the schematics. However, what manufacturing needs on information can still easily be converted into location-based reports.

Standards accounted for

The ISO/IEC 81346 standard supports the creation of schematics that anyone can read. What is an object’s function? Where will the object be placed? Questions like these are easily answered because all of these aspects are taken into account in functionally oriented schematics. The advantages for users are clear:

- Getting started with professional electrical engineering designs is even faster

- Component data for schematics is taken directly from the EPLAN Data Portal

- Standardised engineering data, standardisation templates, application examples, industrial templates and best practices are available with the EPLAN Engineering Standard

New eLearning course: “EPLAN Platform 2025 Update Training”

Speaking of getting started faster: With eLearning courses from EPLAN, the possibilities for users are nearly unlimited. EPLAN provides these materials around the world in up to sixteen languages. What’s special is that all the eLearning materials comply with international standards and are fully localised. The eLearning “EPLAN Platform 2025 Update Training” is completely new and allows users to easily find and play with new functions, receive project planning tips and thereby come to better and faster results. Customised consulting workshops on the EPLAN Platform 2025 are also available upon request.

Digital onboarding: Welcome aboard

To make it even easier for users to start planning with EPLAN, the company has put together a variety of onboarding packages – from digital, independent learning/implementation to partial support or even full support via EPLAN Professional Services. It can include customised implementation in infrastructure, training by the EPLAN Academy and consulting services. Companies are supported throughout their digital journey so that can successfully start working with the software from the very start and get the most out of it.

More information, the News Project and all the eLearning materials can be found at: