Manufacturing

Better With Industry 4.0 and Automation

A comprehensive portfolio of solutions from Rittal and EPLAN supports all steps in the manufacturing process. The data from the digital twin enables a great many processes to be automated during this phase, too, including panel machining, cable fabrication and the cutting of cable ducts or support rails. This is made possible by using manufacturer-neutral standards for data and data communication, which improves interoperability between the various systems.

Rittal offers you fully automated machines so that you can individually process enclosures and cabinets for plant engineering. Aside from providing the virtual prototypes, EPLAN software can also supply step-by-step instructions for the wiring process directly at a workstation. In addition, Rittal Automation Systems delivers everything that makes panel building easier via automation. You reap the benefits of ideal workflows from a single source.

Cutting

The digital twin provides all drilling and cutting data to prepare variable-length components such as DIN rails, cable clamp rails, cable ducts and cable duct covers for assembly.

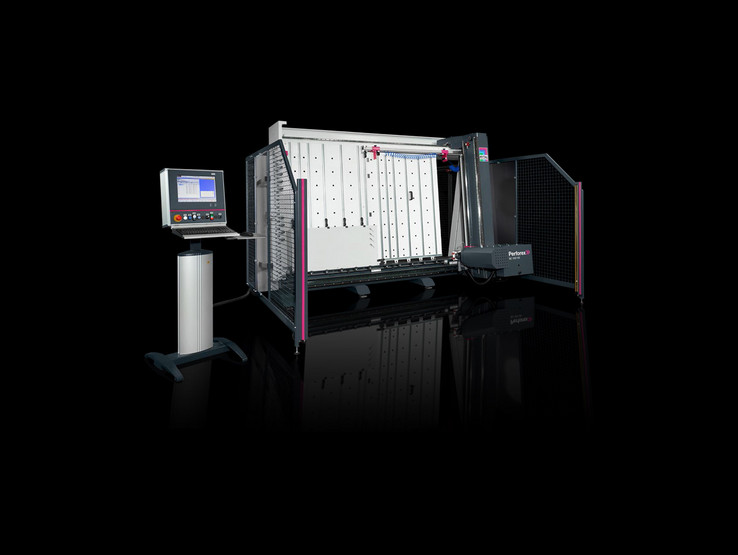

Panel Modification

Based on the drilling and milling data in the digital twin, the housing adaptation and the mechanical machining of the flat parts is automatically carried out by a CNC machine.

Mechanical Installation

2D layouts containing all the information needed for installation work are generated based on where devices are positioned in the digital twin.

Labeling Devices

Device tag data from the digital twin is forwarded to label printers, eliminating manual entry, sorting or editing.

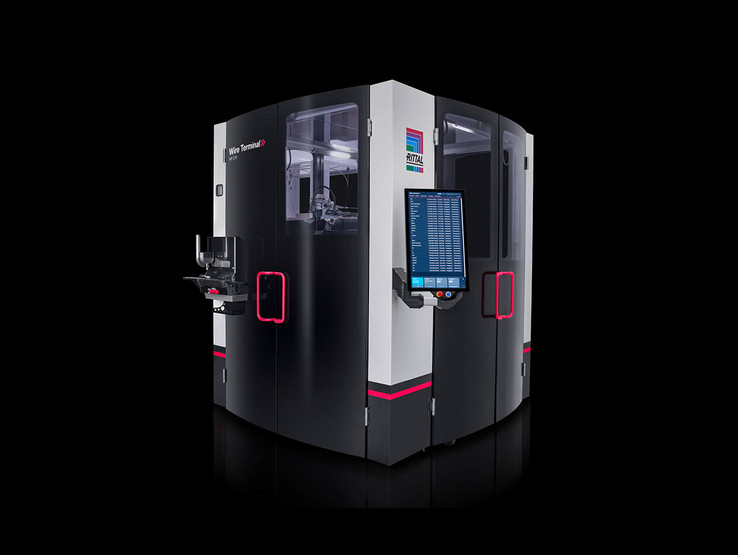

Wire Fabrication

The creation of the digital twin includes, among other things, the definition of the optimal installation paths of the electrical connections from the schematic inside the enclosure and the determination of the necessary lengths for each of the connections.

In combination with the specifications from the schematic for colour, diameter, material type and wire end preparation, the digital twin comprises the data required for manual and fully automatic assembly of a wire or cable. Standardised interfaces also make it possible to provide this data directly for fully automatic wire processing.

Wiring

The wiring information in the digital twin is used to visualize routing paths and necessary connection points for the installation. The completeness of all information in conjunction with the visualization of the installation and connection situation makes it possible to wire the enclosure without a schematic.

Testing

The point-to-point connection lists for wires, cables, terminals and devices help to identify potential faults before commissioning the enclosure.