Engineering

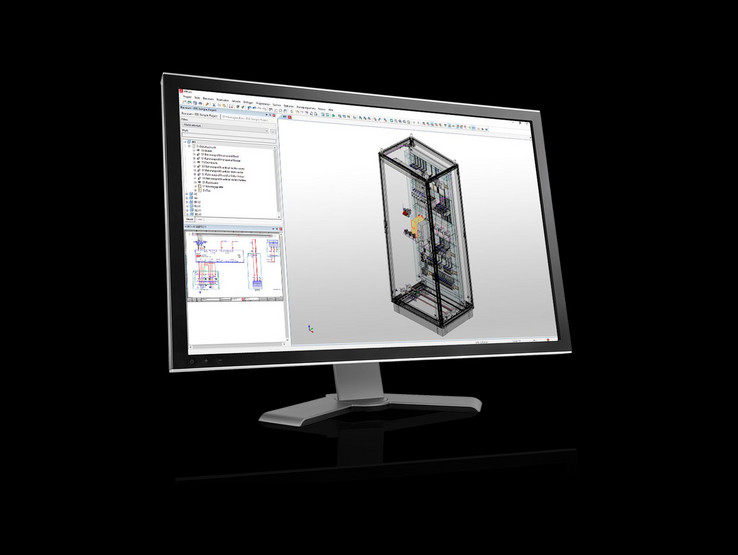

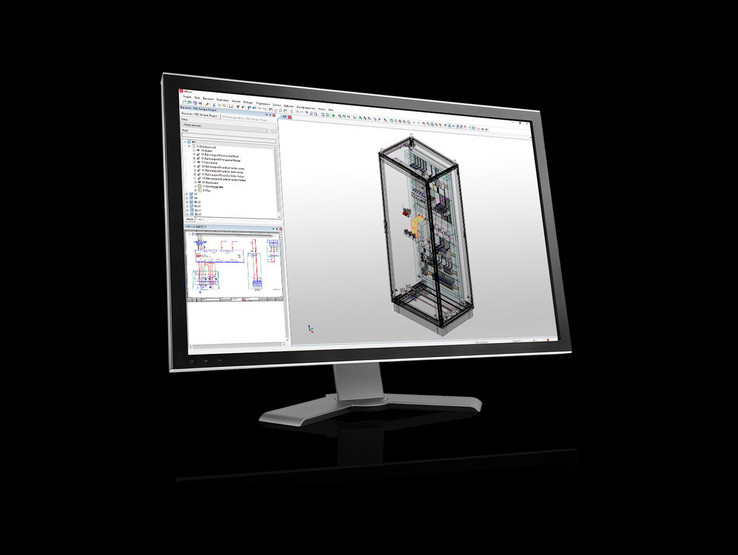

Digitalisation and Prototyping Boost Productivity

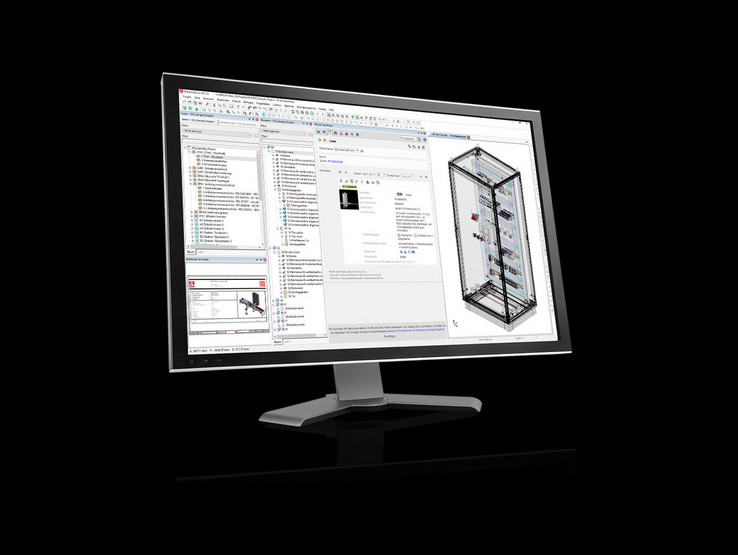

The control cabinet is digitally planned and designed in the engineering department. The software solutions from EPLAN work together perfectly to create the central database for your entire value chain process: step by step, the digital twin of the real-life product is created as a consistent data model. High-quality 3D data depict the virtual prototype’s housing and accessories. This data is complimented by project-specific components and wiring information. As part of this process, all engineering data is available in a centralised solution environment that can also be accessed in the downstream process steps. This way even mass customisation can be automated and implemented in a cost-effective manner.

Technical Specifications

The manufacturer of enclosures and switchgear receives customer data and validates it with regard to the availability of article data, completeness and suitability for all subsequent processes, e.g. in engineering and work preparation. If necessary, the data must be prepared accordingly. Moreover, necessary enclosure options and associated additional process steps are determined.

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN Preplanning

- Keep all your system, machine or building data well-structured and in view at all times

- Preplan fundamental information such as signal, pipework and cable data on a graphical basis for improved guidance

- All relevant staff have easy access to engineering data captured from the early stages of the project – and retain this access throughout and beyond the project

- Using EPLAN Preplanning in the quotation phase and seamlessly transferring data to engineering significantly reduces your development times

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

Technical Consulting & Design

Suitable solutions for the enclosure, the necessary system accessories, the power distribution as well as heating, cooling or climate control are defined.

Value Chain Consulting

- Rittal experts work with customers and use the process analysis tool to identify potential efficiency gains throughout the process chain

- Consulting services deliver practical recommendations for savings

RiPanel

- Simply select enclosure and accessories and configure your new enclosure with ease

- Cut-outs and drilled holes are planned and visualized in 3D in real time

- Save a lot of time – production documents and data are generated automatically at the end of the configuration process: a CAD file for the entire configuration, a CNC file for straightforward machining, data with customer-specific configurations for forwarding to EPLAN Pro Panel

- After the planning stage, you can submit an enquiry for the configuration or order it online directly

Power Engineering

- Our licence-free modular system ensures you benefit from significantly reduced planning, ordering and assembly outlay – simply select assemblies and place them on the graphic

- Component parts lists, technical credentials and documentation are generated automatically

- Technical support is available from Rittal on request

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

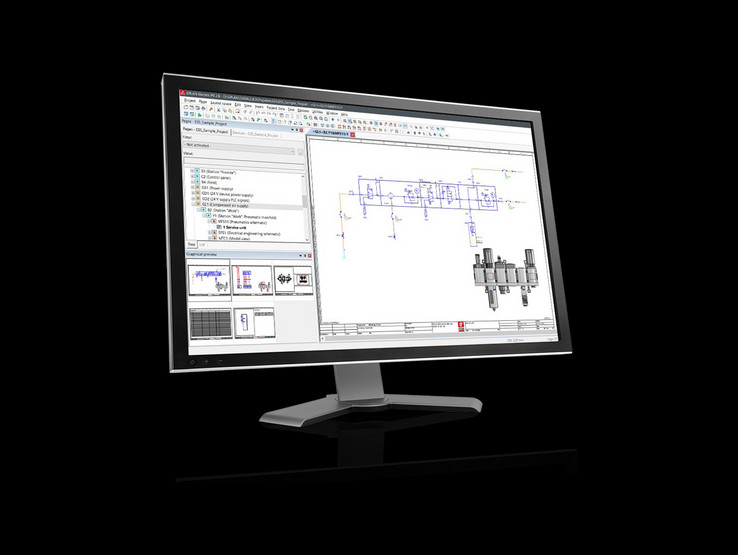

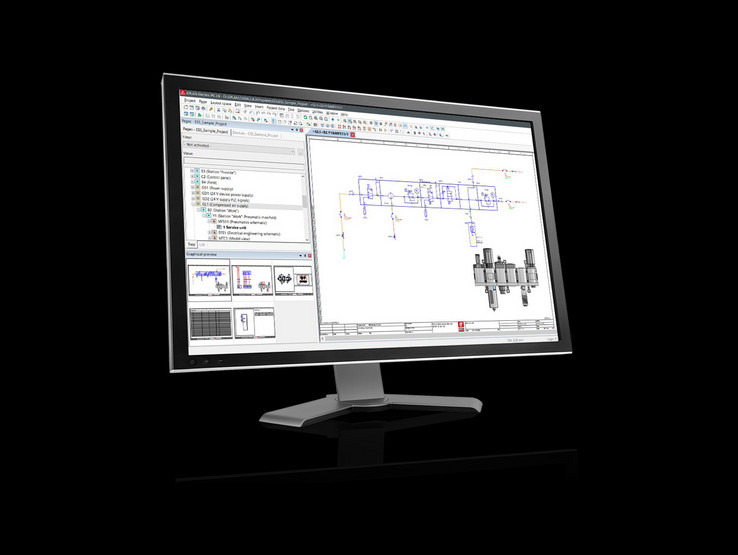

Product Functions Design

Schematic design with ECAD software – the entire value chain subsequently benefits from consistent engineering data .

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN Electric P8

- Choose between a graphical, logical or device-based project planning approach to support different working processes

- Auto-connecting allows you to logically connect schematics symbols in no time at all

- Reports such as terminal diagrams, wiring diagrams or bills of materials are generated automatically

- Features for processing bulk data such as "find and replace" and "edit in Excel" accelerate the design process while increasing quality

EPLAN Fluid

- Save time by speeding up time-consuming steps and minimizing the need to consult specialist departments

- Macro technology enables you to store standards and expertise in the system so they can be reused later on

- Fluid technology can be planned in line with the latest ISO 1219 or IEC 81346 standards with a mechatronic approach

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

Checking & Correcting

The schematic is checked for conformity to standards, completeness and correctness before it is made available for subsequent processes. This way, errors in subsequent processes, e.g. in the unambiguous designation of components or in the complete description of electrical connections, can be avoided. Ideally, this is done automatically with the support of the ECAD software.

EPLAN Electric P8

- Choose between a graphical, logical or device-based project planning approach to support different working processes

- Auto-connecting allows you to logically connect schematics symbols in no time at all

- Reports such as terminal diagrams, wiring diagrams or bills of materials are generated automatically

- Features for processing bulk data such as "find and replace" and "edit in Excel" accelerate the design process while increasing quality

EPLAN Fluid

- Save time by speeding up time-consuming steps and minimizing the need to consult specialist departments

- Macro technology enables you to store standards and expertise in the system so they can be reused later on

- Fluid technology can be planned in line with the latest ISO 1219 or IEC 81346 standards with a mechatronic approach

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

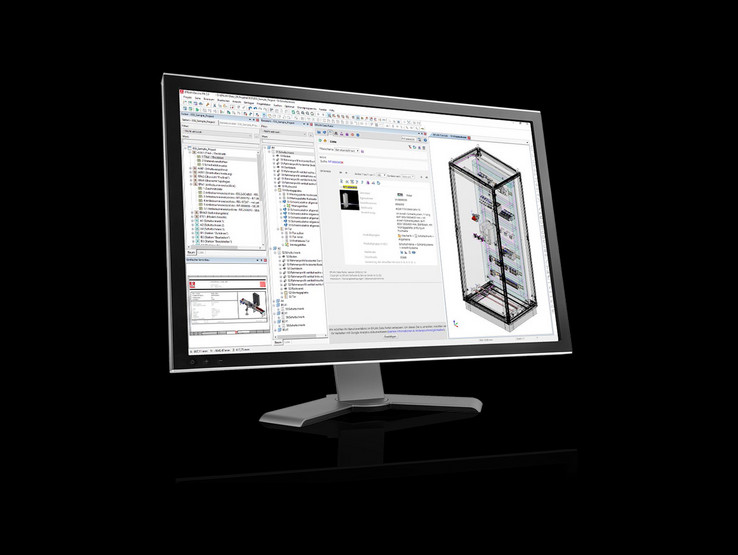

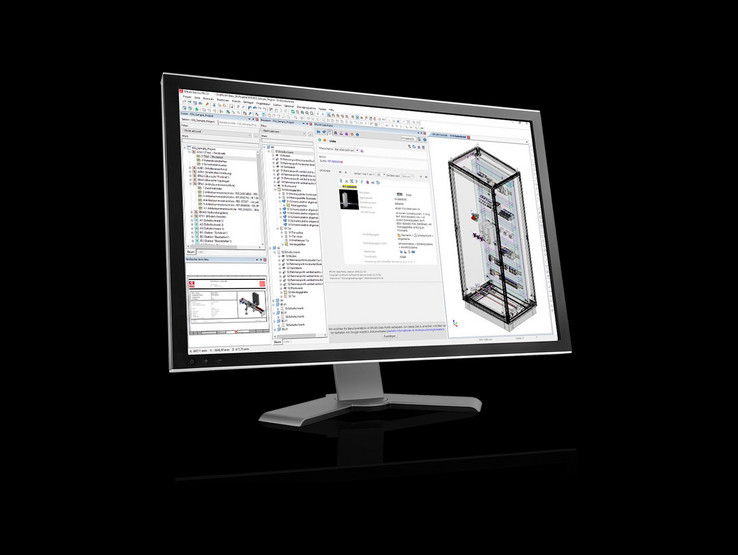

Mechanical Infrastructure

With a view to the customer’s requirements, the location, the environmental conditions and the space required for the installation of the electrical and fluid components specified in the schematic, the appropriate type of enclosure is selected, dimensioned and supplemented with the necessary accessories.

RiPanel

- Simply select enclosure and accessories and configure your new enclosure with ease

- Cut-outs and drilled holes are planned and visualized in 3D in real time

- Save a lot of time – production documents and data are generated automatically at the end of the configuration process: a CAD file for the entire configuration, a CNC file for straightforward machining, data with customer-specific configurations for forwarding to EPLAN Pro Panel

- After the planning stage, you can submit an enquiry for the configuration or order it online directly

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

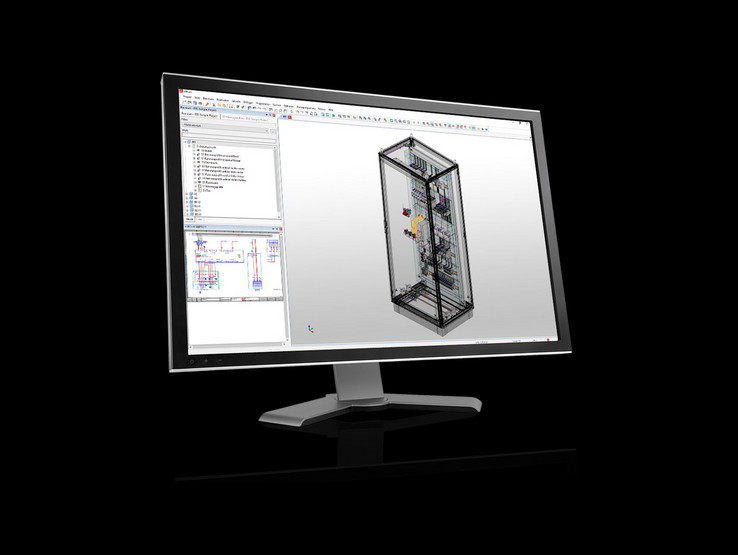

Digital Twin

The digital twin brings great opportunities concerning manual process steps as well as for automation and digitalization of all process steps in panel building, e.g. mechanical processing, wire prefabrication, wiring and terminal assembling.

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

Thermal Design & Dimensioning

Customer requirements, ambient conditions at the installation site, electrotechnical components and their power dissipation as well as the defined assembly layout of the digital twin define the framework conditions for configuring and dimensioning the optimal climate control solution and the correct distribution of the air flows.

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

Thermal Design Integration

- Avoid planning mistakes thanks to the visualization of hot spots and exclusion zones dictated by ventilation requirements

- Minimize downtimes and reduce the number of service assignments

- Lower costs and improve process quality

RiTherm

- RiTherm takes care of all aspects of complex calculations for climate control requirements

- Benefit from huge time savings and improved reliability

- The calculation produces an optimum climate control solution

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW