ECAD from the Cloud

Initial Experiences with EPLAN eBUILD

Using eBUILD by EPLAN allows electrical designers to reap the benefits of cloud-based engineering. This includes the fact that everyone involved in a project is always working with the latest version of the schematics. This also simplifies communication, such as with the shop floor, not to mention with co-workers who install systems around the world. The company Pixargus in Würselen, Germany, near the Dutch and Belgian borders, was one of the first users of EPLAN’s cloud solution – and has been completely won over.

In Greek mythology, the giant Argus had a hundred eyes, only two of which were ever asleep at any one time. This makes him a good eponym for the company Pixargus, in Würselen, Germany, near the tripoint where Belgium, Germany and the Netherlands meet. The company, founded in 1999 out of the renowned Institute for Plastics Processing at RWTH Aachen University, is a specialist for challenging image processing tasks – and has been since the time when “machine vision” was still uncharted territory and Pixargus was a pioneer in the field.

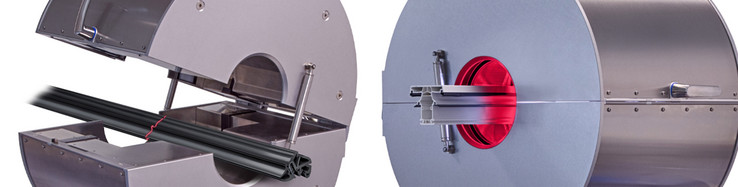

More specifically, the company designs and manufactures systems for the inline inspection of continuous and round materials such as extruded profiles, hoses, cables and strip products made from a wide variety of materials. Pixargus co-founder and Managing Director René Beaujean: “Our systems mostly record the surface quality or the dimensions of the inspected material – and do it at very high resolution and very high speed.” With this core expertise, Pixargus is successful globally as a hidden champion of optical inline quality control.

Making Work Easier for Design Engineers

Each individual system from the company’s broad range of products can be customised as required by clients. Furthermore, Pixargus also designs special machines that use system modules from its regular products.

So there’s plenty for the company’s electrical design engineers to do – and their tasks have already become much easier. When Daniel Reinhardt came on board about two years ago, he immediately introduced EPLAN Cogineer. His reason for this in a nutshell: “I’m not a fan of copy and paste and template projects where there’s the risk of accidentally carrying errors down the line.” From many years of experience, Managing Director Beaujean also knows that this is one of the main sources of errors when creating electrical schematics and has been consistently pursuing the goal of configurable schematics for many years.

First Step: Modular Electrical Designs with Macros

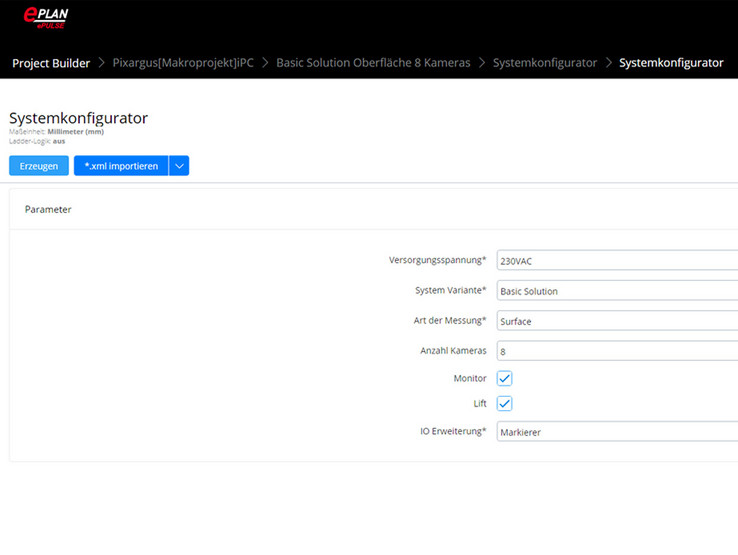

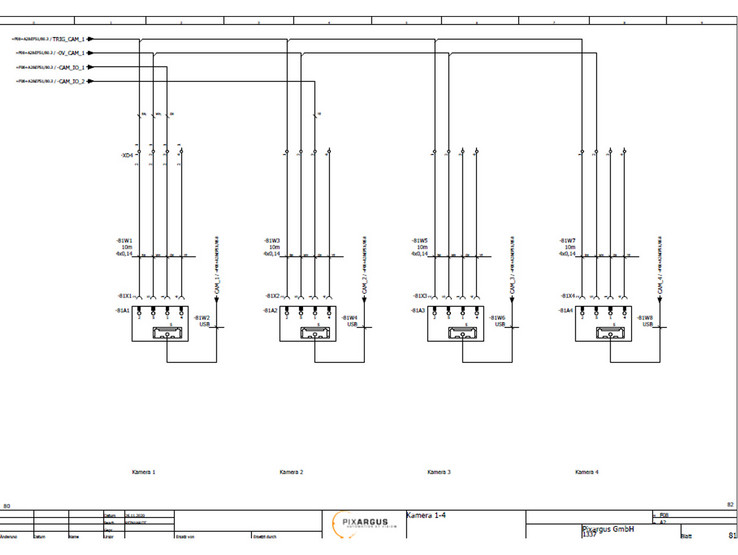

That’s why Reinhardt and his co-workers have stored the systems in electrotechnical modules, each of which is saved as a macro in the ECAD software. This is also used for the options that customers can choose. Reinhardt says: “This way we can generate around 90 per cent of each schematic using macros.”

For example, the various types of power supplies (110 or 220 volts, or American specifications), the number of cameras, the light source (laser, LED, etc.) and other additional options are all stored as macros. The two electrical design engineers click on the corresponding macros in the form they created – and then the schematics are generated automatically.

One of the First Users of Cloud-Based Electrical Engineering

The design engineers made a similarly rapid decision – naturally with the backing of management – for the next step; as EPLAN was pushing ahead with developing cloud-based electrical engineering tools, Pixargus was one of the test users of ePULSE, giving EPLAN’s developers valuable feedback.

The concept and its implementation have been well received, as demonstrated by the fact that Pixargus is a staunch and satisfied user of ePULSE. Reinhardt: “The cloud environment is really good. Solutions we use extensively include eBUILD – for automated cloud-based design – and eVIEW. This tool connects us with the workshop and with the assembly technicians who install our equipment around the world.”

Schematics Always Up to Date – For Everyone Involved

The specific advantage: when the workshop has a request for a change or the assembly technicians alter something, they report it via redlining and via the comments function instead of commenting in a PDF. Once the responsible design engineer has accepted and made the change, the updated schematics are immediately available to everyone involved – conveniently and everywhere.

Reinhardt: “For example, the assembly technicians can also enter the customer-specific assignments of the I/Os on site, so the documentation is then complete.” This saves time and improves the quality of the documentation: “Even very simple notations, for instance about adjusting wire lengths, are now communicated. The technician marks the wire on a PC or laptop and writes a brief comment, we receive notification of it and then confirm the change.”

This also works so well because the ECAD documents are accessible in eVIEW using a web browser – and the documentation is always the latest version. This means that everyone involved is always up to date.

iProfilControl – this efficient, space-saving inspection system on the line is even easier to integrate into a machine layout.

© Pixargus

Pixargus combines proven testing technology for surface inspection and geometry measurement for cost-optimised downsized models.

© Pixargus

The sensor in the DualVision system ProfilControl 7 delivers surface information and dimensional data.

© Pixargus

Cloud-Based ECAD Offers Clear Advantages

The company’s IT-savvy management also sees advantages in the eBUILD cloud solution. Beaujean: “We save IT resources and the administrative effort of updates, yet still everyone involved is always working with the latest software. Aside from which, the cloud-based system has better availability – worldwide and also on mobile devices.”

What about security? Pixargus took a hard, close look at this: “We ourselves also have backups and our own apps in the cloud and were convinced: eBUILD is secure, especially since it’s just the software that’s in the cloud, not the CAD data. The projects remain in our IT infrastructure. The benefits clearly outweigh the risks, and the security is ensured.” The calculation on the commercial side is also in its favour: the payment model is transparent, and in the beginning, users have free access to test the product.

“It’s the way forward for us”

The conclusion for Reinhardt after several months of using eBUILD – where Pixargus was also a pioneer – is clear: “We’re extremely satisfied with the cloud solution from EPLAN and enjoy working with it.” The enthusiasm is also clear: “You can quickly work with the solution and you don’t have to install anything. Cloud-based electrical engineering is the way forward for us.”

Electrical Designer Daniel Reinhardt and Pixargus co-founder and Managing Director René Beaujean next to the System ProfilControl 7. They’ve both been won over by EPLAN eBUILD.

© Pixargus

Pixargus uses the eBUILD cloud software to generate around 90 per cent of the schematics with macros. The system configurator can be used to quickly determined the desired parameters in the

© Pixargus

After inputting just a few characteristics, the software generates the schematics in no time at all.

© Pixargus

Intensively Used: The Improved Data Portal on the Cloud Platform

With the introduction of EPLAN ePULSE, EPLAN Data Portal has also “moved” to the cloud. New features include an improved user interface with smart search functions and even richer data sets based on the Data Standard. Pixargus uses the portal intensively and greatly appreciates it. Reinhardt: “We almost always use components from the portal. The data sets are of very high quality and we can import the data directly into our designs. If I have two component suppliers to choose from, where the price and performance are similar, I take the one that provides better data in Data Portal.”

Author: Holger Jansen, Business Owner Cloud Software Automated Engineering